FRP LINING / FRP COATING

fiberglass coating

What is FRP lining?

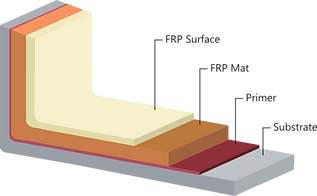

FRP lining stands for Fiber Reinforced Plastic or GRP Glass Fiber Reinforced Plastic or fiberglass pond coating. which is the coordination of the resin material with the fiber mesh The fibers are available in a variety of glass, carbon, aramid, basalt combinations with chemical resistant resins. The resin used today is called Vinyester Epoxy, which is a very high chemical resistant resin. When combined with glass fiber and coated on the surface, it is resistant to acid, alkali, and strong chemicals. excellent

HIGH CORROSION RESISTANCE

HIGH ABRASION RESISTANCE

Features of FRP

-

Very high corrosion resistance compared to other resins

-

Resistant to temperature changes and high temperatures

-

have a long service life

Based on this information, 3 factors make FRP lining suitable for pit coating, pipe coating or areas requiring high corrosion resistance. Can adhere to a variety of surfaces such as concrete, steel, stainless steel, PVC, PP, PVDF, PE, EPS by acting as a corrosion barrier to the surface of the material.

Application Area

-

Wastewater treatment ponds for heavy industry

-

high concentration chemical storage tank

-

Sewage gutter containing chemicals

-

RO pond

-

contact area in a chemical factory

-

Area of contact with concentrated acid, alkali

-

Areas that are difficult to maintain or do not require maintenance

FRP lining installation steps

surface preparation

-

Clean the surface with clean water, clean the cement stains, dirt. Oil or chemical stains should be washed with washable materials. Leave to dry for 1 day.

-

Polishing of corners and surfaces At the inner corner, chamfer with resin mixed with filler, while the outer corner is cut off by 45 degrees, used for a fiberglass mat to form a beautiful edge.

-

Surface inspection, no holes, cracks, bulges, cracks, wounds on various surfaces

Coating work (3 mm. total thickness)

-

1st layer Primer layer to adjust the surface of the face and increase adhesion to the next layer. Start by mixing resin vinyl ester with accelerator and hardener, rolling with 1 roller of thickness approximately 0.25 mm.

-

2nd layer Body base coat is the middle layer. Increase the thickness. Use resin vinyl ester applied together with fiberglass mat 80 gram/m2, thickness 0.7-0.9 mm.

-

Third layer Body base coat is a middle layer. Increased thickness. Use resin vinyl ester to coat with fiberglass mat 80 gram/m2, thickness 0.7-0.9 mm.

-

4th layer Body base coat is a middle layer. Increase thickness. Apply resin vinyl ester together with fiberglass mat 80 gram/m2, thickness 0.7-0.9 mm.

-

5th layer Top coat Middle layer uses resin vinyl ester with glass fiber tissue mat 30

Surface inspection

-

The corners, surfaces, joints and coatings are inspected to be smooth, beautiful, non-porous, or the resin does not cure. Uneven and rough areas to be grinded with a grinder.

Top coating

-

6th layer TOP coat The top layer is resin vinylester mixed with primary paint and parafin wax coated with a roller.

-

7th layer TOP coat The top layer is resin vinylester mixed with primary paint and parafin wax roller coated.